This macro-area deals with the study and development of models describing the behaviour of processes and materials under specific conditions. This is a topic of particular interest in the industrial field, since it allows a better comprehension of materials and product performances and for the research and development of high performance materials.

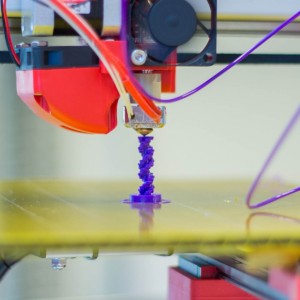

Within this topic, there will be also great attention to the simulation of different phases of the printing process, in different prototyping technologies: a better comprehension of the process is the key factor for its optimization.

One of the main frontiers of the Additive Manufacturing concerns the development of new types of materials to be used with 3D printers.

In the medical and pharmaceutical field, the main interest regards biocompatible materials and materials suitable for cell-culture as far as the printing of living cells, that can be used in regenerative medicine or for drug delivery systems: within this application, the main advantage comes from the possibility of creating a geometry that resembles the patient-specific anatomy, reconstructed from medical images.

In the structural and industrial field there’s the need of materials with specific mechanic and structural characteristics. With the Additive Manufacturing technology it is possible to combine different materials and deploy them into specific patterns, paving the way to the production of final products with resulting mechanical and structural properties that cannot be retrieved through other technologies.

This topic concerns the optimization of the printing process for specific applications or for the printing of materials not available in the market or with very low performances. An example from the plastic prototyping side comes from the printing of the high-deformable materials or silicone with FDM technology. For this purpose, it will be necessary to modify the commonly used printing system and to integrate different curing system, moving towards a new generation of printers.

On the metal prototyping side, an interesting topic regards the printing of alloys with particular mechanical characteristics, such as Shape Memory Alloys (SMA), whose mechanical behavior is highly dependent from the curing temperature: this application needs the development of a specific manufacturing strategy.

The great and detailed diffusion of 3D printing is a key indicator of its versatility. Actually, the project lists a wide range of applications: some of them require the definition of a specific strategy for the application of an existing technology, while others need the development or optimization of printing materials and the adjustment of the prototyping process. Applications involve many different fields, from biology, medicine and pharmacology to more industrial applications like jewellery and to civil engineering, architecture and cultural heritage.

Additive Manufacturing technologies are completely changing lots of production systems, leading to new production paradigms. Moreover, rapid prototyping has a key role in the development of new products and ideas, since it is able to radically shorten the process that goes from the idea to the final product. Thus, there is a constantly growing interest in topics like patenting and proprietary issues that must be studied in relation to the Additive Manufacturing process and applications. Moreover, there is great interest in all the social and legal implication of 3D printing, for example in terms of how it is able to affect the job market.

The rapid production of prototypes, offers new and interesting problems to cognitive, epistemological and ethical reflections. We are facing artifacts that are able to produce new artifacts and that promise a whole range of new functions: cognitive (for instance, tools to improve teaching efficiency), epistemic (new possibilities for the creation of heuristic “models” in scientific research, and the “creation” of new artifacts as epistemic aides), pragmatic/instrumental (personalization of products aiming at different scopes, creation of new artifacts for biological, therapeutical, ludic, design-related support, etc, also enabling a direct or indirect moral mediation).

The interest that is developing around the prototyping is demonstrated not only from the industrial field but also from the academic; many universities worldwide has opened laboratories and academic programs dedicated to theme of “rapid prototyping” and “Digital Factory” (CAMEL, Western Carolina University).

At the national level there is the lack of a reference center for applications of this technology, in industrial and medical field. The proposed center wants to act both as national and international reference not only for the development of new technologies and print materials, but also as a reference point for the use of this technology. This point in particular has profoundly innovative nature and is also reflected in the strategic objectives of the “Terza Missione” promoted by the University of Pavia. In particular, the involvement of many SMEs and local university spinoff, will permit this collaboration with a double benefit: on the one hand for the academic, with the opportunity for its students to interface with the world of work and the other for companies, which may have more awareness of the skills provided by the university.

Rapid prototyping has known a great growth in the recent years: the best known form of prototyping, 3D printing, is increasingly common in a widespread manner, especially at amateur level. The aim of the proposed center is to create a center with multidisciplinary and professional skills, thanks to the presence of experts from different sectors involving in these technologies. This center of reference, highly specialized in the various fields of prototyping, is a unique excellence in Italy.

At national level there are several universities that are moving towards rapid prototyping technologies. Typically, these academic prototyping centers were born from a specific application area, where this technology has been introduced. Therefore they are often limited to the specific field of application. The idea of become a multidisciplinary reference center, gives at this center a new strong competitive nature, national and international level. Rapid prototyping is also a field that has developed in recent years only: it remains, therefore, a field still unexplored, with strong innovation margins and wide spaces of operation. The decision to create a prototyping center in the university will also allow a high level training activities on the subject, that have strategic importance for entering the world of work. This importance is evidenced by a study of Wanted Analytics also reported by Forbes attesting how, in August 2014, 35% of the ads research published by US companies interested in hiring engineers, involved experts 3D printing! The increase in demand for candidates with expertise in the field of 3D printing and additive manufacturing stood at 1.843% in the last four years. But comparing requests between August 2013 and August 2014, this increase rises more than 103%, confirming an important growth.

If you are interested in the official document of the University Strategic Plan, you can download it here.